ELMA Vision CM Alu

SUBMERGED ARC WELDING WITH EFFICIENT MAG POWER SOURCE TECHNOLOGY FROM ELMA-TECH

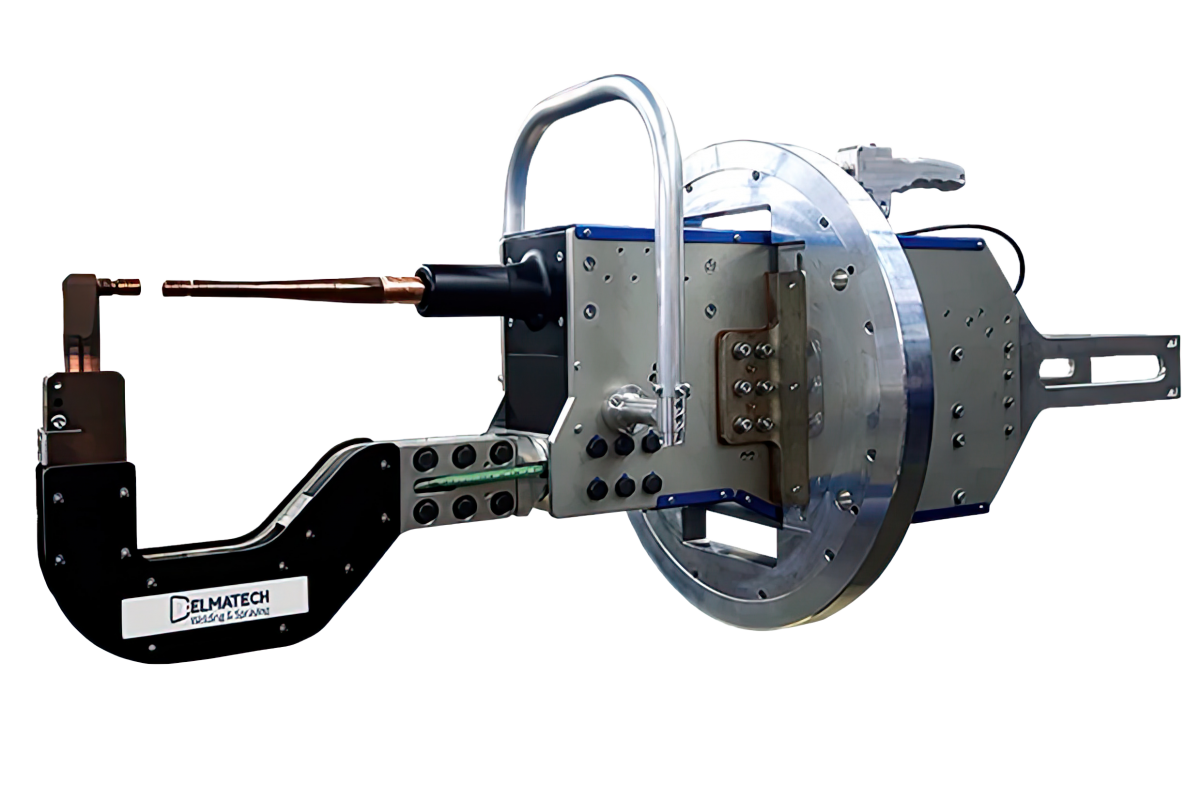

ELMA VISION CM ALUMINUM SPOT WELDING GUN / VMC VISION ALUMINUM CONTROL CABINET

High transformer and cooling performance, approx. 5 kN at 6 bar compressed air network, integrated electronic precision pressure regulator, digital process control

Please contact us for more information.

ELMA Vision CM Alu – ELMATECH ALUMINUM SPOT WELDING SYSTEM ELMA VISION CM ALU INCLUDING CONTROL CABINET:

- Digital process control

- VISION AV aluminum control cabinet

- Welding program for high- and ultra-high-strength steels (other programs on request)

- Static/dynamic control with Spot QS Viewer

- Linear potentiometer for sheet thickness detection

- Hose package 6 m (can be plugged in on both sides)

- Slewing ring and grip ring

- 16mm copper chrome zirconium electrode caps on standard electrode shafts

- Hall installation plate for connecting ELMA-Tech spot welding guns, “aluminum” version

ELMA Vision CM Alu – EFFICIENT HALL INSTALLATION UNIT FOR CONNECTING ELMA-TECH SPOT WELDING GUNS:

The hall installation plate (HIP) is a media supply unit for connecting ELMA-Tech spot welding guns in the “aluminum” version in 10 kHz medium-frequency inverter technology. A digital display flow monitor, water flow and return, distributor, pressure gauge and a compressed air maintenance unit complete the equipment of the hall installation unit. An external water recooling unit (SMC HRS 50) for optimal cooling of the spot welding guns and the control cabinet is optionally available.