ELMA Control Vision

ELMA Control Vision

SPOT WELDING WITH HIGHLY EFFICIENT PLIERS FROM ELMA-TECH

3-phase connection, 400 V/50 Hz, maximum power 130 kVA, clamp: voltage 560 V / 10 kHz, maximum current (eff.) 230 A / 300 A, compressed air (proportional valve) 6-10 bar.

Please contact us for more details.

Characteristics

ELMA CONTROL VISION – FULLY AUTOMATIC SPOT WELDING PROCESS CONTROL :

- Modular system

- Compatible with all 10 kHz ELMA-Tech transformer clamps

- Precise process control, energy control and shunt detection

- Reproducible welding quality

- Connection for external cooling with water monitors for cooling clamps, transformers, cables and electrodes

- Hall installation plate (HIP)

- Connection to conventional bus systems

- Automatic recognition of material type and total sheet thickness

- Impact points

Spot welding guns C/CM & VM/CR & VR

ELMA CONTROL VISION – SELF-ADJUSTING SPOT WELDING GUNS FROM ELMATECH:

- High welding currents, low number of current transitions

- Integrated quality assurance system ELMA-QS with a clear quality statement

- Over the welding point

- Spot welding in automatic VISION mode

- Precise guidance thanks to the light weight of the pliers

Transformer industry spot welding guns VM/CM & VR/CR

ELMA CONTROL VISION – ELMATECH SPOT WELDING GUNS FOR INDUSTRIAL OPERATION:

- 10 kHz medium frequency transformer

- Low pliers weight (2/3 lighter than conventional pliers)

- High output currents up to 15 kA

- Automatic adjustment of the electrode force

- Integrated servo proportional valve

- Automatic sheet thickness detection

- Height-adjustable orbital ring (VM / CM)

- Hose and cable package (10 meters) with quick release

- Shut-off valve for water flow (non-return valve in the return) for changing caps

- Cylinder, piston rod and main bearing guided in precision needle bearings

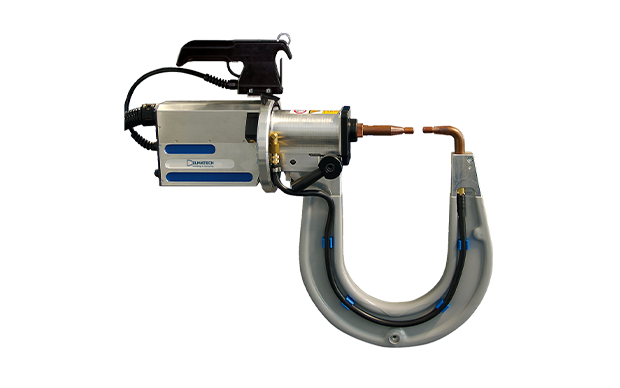

Transformer spot welding guns X-AV & C-AV

ELMA CONTROL VISION – X-AV AND C-AV SPOT WELDING GUNS FROM ELMATECH:

- 10 kHz medium frequency transformer, weight 4 kg

- Low weight of the pliers

- Automatic sheet thickness detection, electrode force adjustment

- High output currents up to 13 kA

- Ultra-light hose and cable package (6 or 10* meters)

- Orbital ring 360°

C-AV:

- Electrode arm quick-change system

- Standard electrode arms: immersion depth 40 – 500 mm

- Expanding the opening angle by loosening the tension lock

X-AV:

- Precision needle bearing mechanics

- Maximum opening angle 25°

- Standard – electrode arms up to 450 mm